(4) Hardcopy

The engine monitor system sends hardcopies of the operator station CRT indications to the printer.

3.3.2 ENGINE CONTROL ROOM OOPERATOR STATION

The engine control room (ECR) operator station function consists of the following functions. This function can allow the trainee to experience monitoring and operation in a simulated engine control room as if actually onboard.

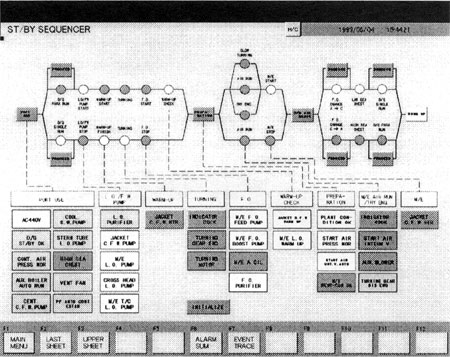

The simulator has stand-by sequence control system so that the trainee can easily operate and experience the engine plant operation from port rest mode to rung up mode, shown in Fig.7.

(1) Main engine remote control system

With the main engine remote control system on the ECR operator station CRT, the trainees can operate the main engine air-run control and sequential logic control and monitoring speed control and emergency shutdown etc.

(2) Stand-by sequence control system operation

With the stand-by sequential control system on the ECR operator station CRT, the trainees can operate the main engine plant automatically and sequentially through port use (port rest) mode, preparation mode, stand by and maneuvering mode and rung up (normal sea going) mode.

Fig. 7 Display Example of ECR Operator Station

- Stand-by sequence control system -

(3) Generator control system

With the generator control system on the ECR operator station CRT, the trainees can operate the generator engine remote start / stop control power and frequency control, synchronizing control, emergency shutdown etc.

(4) Fuel oil viscosity control system operation

With the fuel oil viscosity control system on the ECR operator station CRT, the trainees can operate fuel viscosity control for the main engine and for the generator engines.

(5) Group starter operation

With the group starter on the ECR operator station CRT, the trainees can operate major machinery around the main engine.

(6) Reefer container operation

With the reefer container on the ECR operator station CRT, the trainees can change the electric load of the generator.

3.3.3 ENGINE ROOM OPERATOR STATION FUNCTION

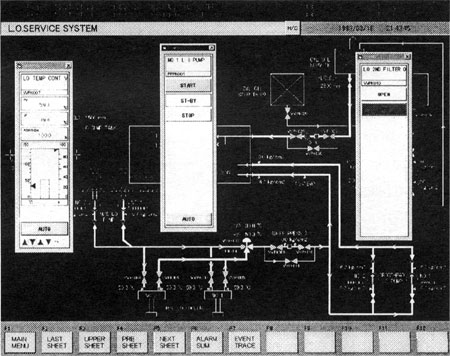

The engine room (ER) operator station function consists of the following functions. This function can allow the trainee to experience monitoring and operation in a simulated engine control room as if actually onboard. An example of the ER operator station CRT display is shown in Fig. 8.

(1) Machine side machinery monitoring

The trainee can monitor the operation status of all machine side machinery, valves and piping system in a simulated engine room on the ER operator station CRT. For example, the pump is running or stopped, the valve is opened or closed, the control valve is 50% opened and pressure is 0.9 MPa.

(2) Machine side machinery operation

The trainee can operate all machine side machinery, piping system with valves in a simulated engine room on the ER operator station CRT. For example, start or stop pumps, open or close valves and open control valve manually.

Fig. 8 Display Example of ER Operator Station

- Piping and machinery operation window -

(3) Main engine local operation

The trainee can operate the local stand of the main diesel engine in a simulated engine room on the ER operator station CRT. (shown in Fig.9) For example, engage or disengage the turning gear, start or stop turning gear motor and start or stop auxiliary blowers.

(4) Generator diesel engine machine side operation

The trainee can operate the local operation panel of the generator diesel engine in a simulated engine room on the ER operator station CRT. For example, start or stop the generator diesel engine and start or stop the priming L.O. pump.

BACK CONTENTS NEXT