With the above software, the simulator faithfully calculates and simulates the actual ship and machinery behavior.

Fig. 4 Operation Example of IDOL (CRT display)

3. SIMULATOR FUNCTION

The function of each computer making up the simulator system is shown as followings. All functions are connected so as to realize a training environment similar to an actual ship and easy operation of the simulator system, repeatable training and other factors.

3.1 SIMULATION SERVER FUNCTION

The simulation server has simulation plant models and calculation software and server application software, as follows (simulation execution function):

(1) Plant model calculation

(2) Control logic calculation

(3) Instructor server... refer to 3.2

(4) Operator station... refer to 3.3

3.2 INSTRUCTOR WORKSTAI ON FUNCTION

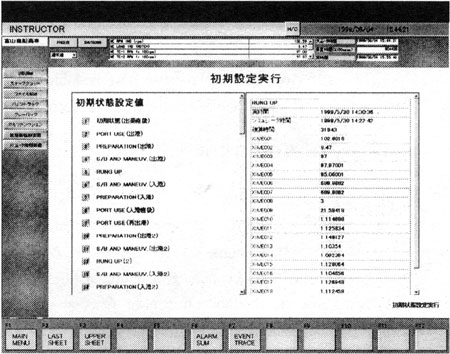

The instructor workstation has simulation control and management software (function) with effective graphical user interface. An example of instructor workstation CRT display is shown in Fig.5.

3.2.1 SIMULATION CONTROL

The instructor can easily control and manage simulation according to the training situation.

Simulation control function consists of the following:

(1) Start simulator

The instructor can start the simulator system before the training session (simulation).

(2) Shut down simulator

The instructor can shut down the simulator system after the training session (simulation).

(3) Run simulation

The instructor can run the simulation whenever he wants to during the training session (simulation).

(4) Freeze simulation

The instructor can freeze the simulation whenever he wants to during the training session (simulation).

Fig. 5 Display Example of Instructor Workstation

〜 Initial Condition Set Function 〜

3.2.2 SIMULATION DATA CONTROL AND MANAGEMENT

The instructor can easily set various training situation.

Simulation data control and management function consists of the following:

(1) Initial condition set

The instructor can select and set the initial condition data from 80 stored data files (including 40 snapshot data files) during the training session (simulation). The initial condition data represents past stored simulations, and various status of plant and machinery.

(2) Simulation speed change

The instructor can select the simulation time interval (for example, 1/2, 1, 2 times) during the training session (simulation).

(3) Snapshot of the simulation

The instructor can take up to 40 snapshot data files during the training session (simulation).

(4) Snapshot data file transfer

The instructor can transfer the snapshot data file into the initial condition data file.

(5) Constants set

The instructor can set some constant data of external / internal conditions (constants) during the training session (simulation). Such adjustable values are those that the engineer can not freely regulate, for example, weather disturbance, engine room temperature, seawater temperature, and be provided by the easy CRT operation.

BACK CONTENTS NEXT