|

The DAIHATSU New 4-stroke Medium Speed Diesel Engine DC-17

Ryou Matsushita

Daihatsu Diesel Mfg. Co., Ltd.

1. Introduction

In addition to low fuel oil and lubricating oil consumption to reduce the running cost, high reliability and durability aiming at maintenance-free are required of 4-stroke medium speed diesel engine.

To much not only these requirements of direct users but also the needs of environmental conservation, DAIHATSU DIESEL developed the new compact 4-stroke medium speed diesel engine DC-17.

DC-17, which DAIHATSU introduced at the beginning of 21st century, is mainly fit for auxiliary engine of bulk carrier. DC-17 covers the lowest power output ranges of marine auxiliary engine that run mainly on heavy fuel oil.

2. Concepts

(1) High Reliability and Durability

(2) Low Maintenance Cost

(3) Environmental Protection and Harmony

(4) Compactness

(5) High Efficiency & Performance

(6) User Friendly

(1)-(5) concepts are the same as our DK engine series.

In addition to these concepts, (6)User Friendly was added at the development of the DC-17.

It means simple and easy installation and handling of the engine.

3. Principal data

Fig.1 5,6DC-17 Principal data

| Engine Model |

5DC-17 |

6DC-17 |

| Number of Cylinder |

5 |

6 |

| Cylinder Bore x Piston Stoke (mm) |

φ170 x 270 |

| Stroke/Bore-Ratio |

1.59 |

| Engine Speed (min-1) |

900 |

1,000 |

900 |

1,000 |

| Piston Speed(m/s) |

8.1 |

9.0 |

8.1 |

9.0 |

| Generator Output (kWe) |

440 |

560 |

| Break Mean Effective Pressure

(MPa) |

2.09 |

1.88 |

2.21 |

1.99 |

| Max. Combustion Pressure (MPa) |

16 |

Fuel Oil

Engine dry Mass (kg) |

up to 700 mm2/s

@ 50℃ (CIMAC H55) |

| 5,600 |

6,250 |

| Generator Set dry Mass (kg) |

9,930 |

11,000 |

|

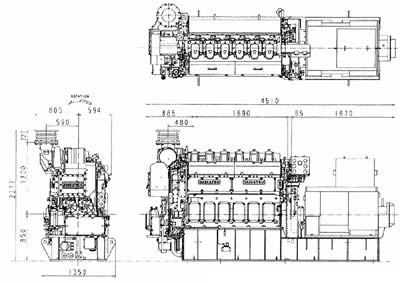

Fig.2 Appearance

|

(拡大画面:102KB)

|

|

Fig.3 Appearance (photograph)

6DC-17

Fig.4 Cross section

Cylinder Head

・Special cast iron for high resistance to heat and pressure

・Optional swirl port

・Effective cooling of F.O. injection valve area

・Hydreulically tightened four studs

Exhaust Pipe

・DSP (Single pipe) system

・Optimal matching of inlet and exhaust timing

・Passage design for maximum turbo charger efficiency

Cylinder Liner

・Special cast iron material for durability

・Use of protect ring

・Optimal cooling design

Frame

・High rigidity monoblock structure

・Hydraulic tightening for main bearing holder and side bolt

・Good accessibility for inspection and maintenance

・Frame casting with cooling water and air passage

・L.O. passage drilled into frame

Main Metal / Crankpin Metal

・Aluminium metal alloy for maximum resistance to wear, corrosion, and pressure.

Fuel Injection System

・Block type high-pressure pipe

・Mono-block plunger barrel

・Non-cooled fuel nozzle

Piston

・High compression ratio (S/B=1.59) and optimal combustion chamber design

・3 rings

・Top & 2nd ring groove hardened

Cam and Camshaft

・Large diameter cams for durability against high F.O. injection pressure

・Two piece unit cam

Connecting Rod

・Horizontally cut 3 piece design

・Big end portion tightened hydraulically

Crank Shaft

・Manufactured by CGF method

・Dynamic analysis for optimum design

・Shaft diameter for optimum oil film thickness

・Highly balanced

|