|

3 SIMULATION ENVIRONMENT

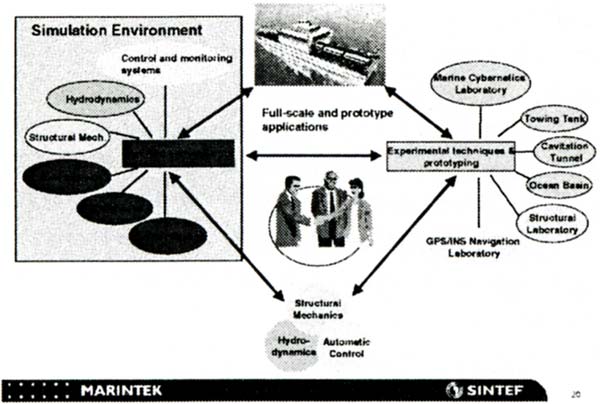

Fig. 5. Simulation Environment.

Extended R&D Services

MARINTEK has established a Simulation Environment that consists of hydrodynamic, automatic control and structural strength modules connected together using the HLA standard. Standard software packages for visualization and electronic chart are used to visualize the motion of the vehicles. The Simulation Environment is used to visualize model tests, simulate and demonstrate different prototype applications. Combining both numerical tools and model tests in the hydrodynamic laboratories provides a unique possibility to develop new monitoring and control systems for marine vehicles. In cooperation with Norwegian University of Science and Technology (NTNU), MARINTEK can perform tests in Towing Tank, Ocean Basin, Cavitation Tunnel, Marine Cybernetic Laboratory, Structural Laboratory and GPSL[NS Laboratory to derive accurate models of ships, propulsors, structures and motion sensors. The Fig. 5 shows how both numerical methods and model tests will provide the best possible solution for each application.

In the process of developing a realistic simulator for product development, the ship models are tested in our hydrodynamic laboratories. Model tests like manoeuvring tests, seakeeping and captive model tests are used to generate a feasible mathematical model of the vehicle dynamics. Dependent on the use of simulator, the accuracy of the model will vary. In control system design, a simplified model can be used. For training purpose, the ship model will include realistic environmental effects like induced wave forces, current and wind effects and also the effects of failed propulsion units and motion sensor failures.

Examples of products and services developed the last years using the Simulation Environment are:

・Development of a joystick control system for FerryCat.

・Development of a hull monitoring system.

・Effects of a bow azimuth thruster on a bulk ship.

・Effects of a bow thruster on a trawler included the trawl.

・Training simulator for a bulk ship passing the Akselsundet at Spitsbergen.

・Visualization of a landing of an Unmanned Air Vehicle (UAV) on a naval ship.

4 EXAMPLE - JOYSTICK CONTROL SYSTEM FOR THE FERRYCAT

4.1 FerryCat.

The FerryCatTM 120 is a high-speed aluminium catamaran built by Fjellstrand AS and is an innovation in the field of commuter ferries, see Fig. 6. The ferry will have a capacity of 112 cars and 400 passengers, and will be capable of speeds of 22-24 knots, using a recently developed propulsion system, denoted Azipull propulsion system (Azimuthing pulling propeller) from Rolls-Royce Marine AS. The propulsion system consists of four propeller units, one at each "corner" of the vessel. The ferry will be steered from a wheelhouse equipped with an operation bridge, which can be rotated 180 degrees, depending on the direction of travel of the ferry. The new ferry will provide considerable improvements for passengers travel time, a more comfortable journey and quicker embarkation and disembarkation.

|

Fig. 6.

|

A double ended catamaran ferry - FerryCat.

|

4.2 Software-in-the-loop simulator

Fig. 7. Software-in-the-loop simulator for joystick control system.

FerryCat PC simulator

The FerryCat PC simulator is developed as a tool for designing the joystick control system for the FerryCat, Fig. 7. The simulator consists of the following modules:

・Ship (hull force, wind and current effects)

・Propulsion (force and power for each Azipull)

・Control system (joystick and autopilot control)

・Navigation (GPS, gyrocompass, speedlog and wind sensor)

・Electronic Chart (visualisation and navigation tool)

・3D Terrain (visualisation)

・GUI (Graphical User Interface and 3 axis Joystick)

Thy ship model was developed using MARINTEK's hydrodynamic software package VERES to derive the hydrodynamic parameters. Further static wind and current effects were calculated using CFD-calculations done by CFD-norway, see [7].

The propulsion models were made by Rolls-Royce Marine AS and are based on extensive model tests done at MARINTEK and other hydrodynamics facilities. The propulsion model also includes a model of the rpm, pitch and angle dynamics. The source code is developed in MATLAB/Simulink environment and executable code is generated as a DLL. The DLL is then connected to the simulator using the Java Native Interface (JNI) mechanism. All modules or federates interfaces are coded in Java.

The Norwegian University of Science and Technology (NTNU) has developed mathematical models of gyrocompass, GPS, speedlog and wind sensor and are all included in the Navigation System module. This module transforms the real ship motion into proper motion sensor signals. Notice that the real ship motion is presented in the terrain visualization software, whilst the human machine interface and control system is based on motion sensor data.

4.3 Hardware-in-the-loop simulator.

The next step in the development phase was to interface the real hardware solution into the simulator. The control software was implemented into Rolls-Royce proprietary real-time control platform denoted Comano. By comparing the commands from the simulated control system with the real commands from the target solution, the target solution was found to be identical with the software-in-the-loop solution. Both the real joystick and the real panel for the operator were used in this simulator, see Fig. 8. In the last step of the process before installation on the ship, several modifications were performed using the hardware-in-the-loop simulator based on input from the operators.

Fig. 8. Hardware-in-the-loop simulator.

4.4 Target solution

As the last step in the process, the final solution was installed and tested in full scale. The joystick control system was successfully tuned within a few hours. Manoeuvring test like turning circle and zig-zag tests (10/10 and 20/20) were performed to develop a more accurate ship model used for training purposes. Another improvement is to include model of motion sensor failures and propulsion failures to use the simulator for Failure Mode and Effect Analysis (FMEA).

5 CONCLUSION

The Simulation Environment provides an effect tool for prototype development of ship monitoring and control systems. MARINTEK will integrate different methods like numerical calculation and in addition perform necessary model tests to provide accurate ship models for different simulation purposes. The HLA is a powerful tool for integrating different well-proven numerical modules for hydrodynamics, automatic control and structural strength methods into a synthetic environment. As far as possible COTS components will be used for visualisation and human-machine interface.

The development of a joystick control system for the FerryCat application has shown that this environment has been an efficient tool and development platform for common understanding and problem solution for development of new industrial products.

REFERENCES

[3] NATO Industrial Advisory Group Report: NIAG-D(2000)9 AC/141(NG-6)D/25.

BIOGRAPHY

Dr.ing. Svein P. Berge is principal research engineer at MARINTEK. In the period from 1989 to 1995 he worked as a project manager at Kværner Fjellstrand a.s and was responsible for developing flight control system and ride control system for High Speed Crafts. He is one of the inventors of the Fjellstrand Motion Dampening System (Fjellstrand MDSTM). Presently he is working most of his time at MARINTEK with simulator development and design of marine control system for both seakeeping and manoeuvring applications.

Dr.ing. Gunnar Nyland took his doctoral degree in physics at the Norwegian Institute of Technology in 1996. He worked at Norsk Hydro corporate research centre in Porsgrunn from 1996 to 2000 on non-Newtonian fluid dynamics and polymer technology, before he joined the R&T department at Rolls-Royce Marine in Ulsteinvik, Norway. Currently he is responsible for the modelling and simulation activity.

|