|

8. 周知・情報交換活動・資料作成

周知情報交換活動用資料としては、平成14年度までの事業成果を中心に、機械的殺滅法の有効性を主体とする次ページ以降の新たな資料を作成した。

Development of Ballast Water Treatment System on board Ship

Takeaki KIKUCHI

The Japan Association of Marine Safety

KEYWORD: ballast water, development of treatment systems. mechanical treatment method

ABSTRACT

Various treatment technologies of ship's ballast water, such as physical and chemical processing methods are under development in various countries in the world.

The Japan Association or Marine Safety has been pushing forward research and development of ballast water treatment technology since 1992, under assistance of the Nippon Foundation, and conducted experiments in chemical, heat, ozonization, electro-chemical and mechanical treatments respectively.

The results through our experiments by these methods are showing that they can remove, inactivate or kill aquatic organisms in ballast water.

We also found out through our experiments that the mechanical processing method using a pipe with special structure in ballasting system was to be the most suitable system, based on these aspects such as installation and operational utility on board ship, i.e. easy operation, effectiveness on marine organisms, safety an operating, cost effectiveness, environmental impact.

We are pushing forward the development of a prototype of the pipe with special structure so called "special pipe", which could be effective and convenient, while watching and participating international discussion on ballast water treatment standards.

1. INTRODUCTION

The spreading of harmful aquatic organisms including noxious plankton and plankton causing red tide on a global basis is becoming an international issue. The spreading of such aquatic organisms is considered to be generated by movement of aquaculture seeds and saplings, transferred through discharge of ship's ballast water, etc.

Among these expanding factors, the work on development of international instruments with respect to prevention of transferring aquatic organisms through ship's ballast water has been pushed forward in International Maritime Organization (IMO) aimed at 2003. However, we cannot find a practicable and efficient technology at present, which will efficiently prevent transferal of marine organisms, thus minimizing the environmental impact applicable to ships, and being cost effective.

Our study has been aimed and conducted, at the development of practicable ballast water treatment technology with less environmental impact, using low cost and without major conversion to structure and equipment on board Ship. The study went for various technologies such as chemical, heat, organization, and electro chemical treatments respectively.

We are considering the special pipe" technology to be the most suitable to achieve the objectives and are pushing forward its further development. We consider that there are some prospects for its practical use.

The results of research are as follows.

2. TREATMENT TECHNIQUES OF BALLAST WATER

Any new ballast water treatment techniques should meet the following criteria; ship's safety, operational complexity, and capability for being installed on board ships, cost effectiveness and level of consequential environment impacts in addition to the effectiveness or treatment.

Including the method that we experimented on, we compared various processing technology and showed them in the following. 1)2)3)4)5)

(1) Ballast water exchange

The main feature of the ballast water exchange at sea is that it is practicable to use the existing facilities already installed on ships.

(2) Filtering method

This method can remove organisms larger than the mesh of the filter. However, filtering devices may become larger so that can be operated at a reasonable capacity this may cause difficulties for installation on many existing ships.

(3) UV radiation method

This method is considered to have a high eliminating effect on various organisms. However, the UV generating system is considered to be expensive and large, and also it becomes harder to operate and install on ships and further consumes excessive energy.

(4) Heating method

The heating method is also considered to have a high eliminating effect on various organisms. However, the heating equipment is thought to be expensive, large, and inconvenient due to increased corrosion and distortion of the hulls of ships.

(5) The mechanical processing in ballast piping system

This method is more effective against organisms that are the size of phytoplankton or larger. In addition, this method requires only a small size of device with low cost, so it is considered as a technically easy to operate and install.

(6) Chlorine method

The chlorine method has an excellent eliminating effect, however the chlorine generating system is considered to be expensive and large. Storing the chemical agent on board requires a large space. The environmental impacts that may be caused by this method are also considered as a disadvantage.

(7) Hydrogen peroxide method

The effectiveness of elimination by using a hydrogen peroxide method is excellent. However, the hydrogen peroxide generating system is considered to be expensive and large; and storing the chemical agent on board requires a large space. It has also the disadvantage of possibly causing environmental impacts.

(8) Ozone method

The ozone method has an eliminating effect. The ozone generating facility, however, is considered expensive and large. The environmental impact by ozone is less than other chemical treatment method.

Following these characteristics of each treatment technique, we are considering mechanical treatment method in ballast piping system is the most realistic method, therefore we continue to evaluate this technology and are pushing ahead with research and development.

Here we show outline of mechanical treatment method by the "special pipe" which is being developed by us.

3. TREATMENT MECHANISM OF THE "SPECIAL PIPE"

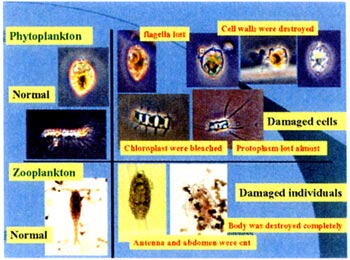

The special pipe is remodeled to improve mechanical efficiency such as shear stress and cavitations to the organisms in water. Organisms in the water are eliminated or rendered harmless while loading and/or discharging ballast water (Fig. 1).

| (拡大画面:54KB) |

|

| Fig. 1 Photograph of normal and terminated Organisms |

4. STRUCTURE OF THE "SPECIAL PIPE"

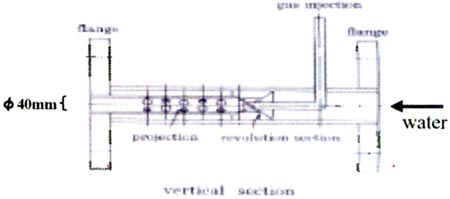

The initial "special pipe" which had been researched and developed is formed with 3 parts, i.e. gas injection, revolution and projection (Fig. 2). However, we considered that this structure was not to be suitable for practical use, because its pressure loss in passing water was large and it is predicted that when its scale improved by this structure, causes less damage effect on organisms.

Study was then done on the new pipe generating shear stress and cavitations, ensuring the same or more damage effect on marine organisms and reducing the pressure loss required while improving its scale.

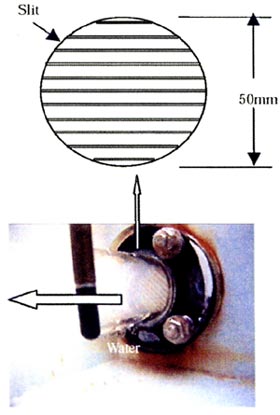

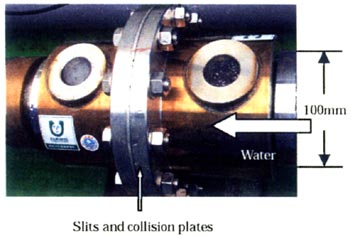

As a result, it became clear that the pipe of extremely simple structure with a plate with slits in it (the improved special pipe) could meet our demands. (Fig. 3)

5. EFFECTIVENESS OF THE IMPROVED SPECIAL PIPE

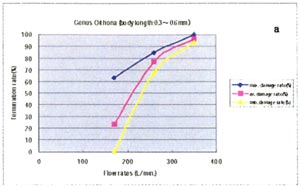

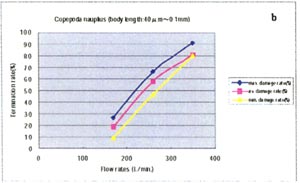

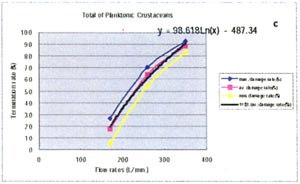

The improved special pipe system can eliminate about 90% of total planktonic Crustacean (zooplankton) in natural seawater (Fig. 4c). This effectiveness was obtained using 60% of the energy of the initial special pipe. In this way, the special pipe system was improved with respect to both the termination effect and the energy efficiency. Also, the improved special pipe system can eliminate larger species (Fig. 4a and c) by providing higher flow rates (see Fig. 4a, b and c).

|

| Fig. 2 Structure of the first special ballast pipe |

|

| Fig. 3 Structure of the improved special pipe |

| (拡大画面:30KB) |

|

| (拡大画面:29KB) |

|

| (拡大画面:30KB) |

|

| Fig. 4 Result of experiments for one-time treatment using the improved special

pipe system |

6. THE PRESENT RESEARCH AND DEVELOPMENT

It also becomes clear that inserting an additional plate for collision at the down stream side of the slits plate in the pipe can improve the effectiveness on organisms with few increasing of pressure loss, by our later research.

Following these results, the pipe (device) with capability of water treatment by 100m3/hr of flow rate was designed and produced (Fig. 5), for our field experiment.

We are now conducting experiments on effectiveness on various aquatic organisms, and on solving blockade problem of the device by particle matter in the water passing through the pipe. During our experiment, we observed that this system showed enough effects on most phytoplankton and zooplankton (including Meroplankton, such as Planktonik larvae stage of Benthos). Although we observed that no blockade of the device occurred during our experiment by using natural seawater in a harbor, the pipe has a device to solve such blockage easily.

|

| Fig. 5 The improved special pipe (correspond to flow rate 100m3/hr) |

ACKNOWLEDGEMENT

This research and development has been conducted, under the guidance of Dr. Hiroshi Tokuda, Ex- Professor (The University of Tokyo), Dr. Hiroharu Kato, Professor, the Toyo University, and Dr. Yasuo Fukuyo Assistant Professor, the University of Tokyo, and under the assistance of the Nippon Foundation. We express our gratitude.

REFERENCES

| 1) |

Oemcke, D(1999): The Treatment of Ship Ballast Water, EcoPorts Monograph Series

No.18 |

| 2) |

The Japan Association of Marine Safety (1992): Study report on preventive

measures against the spread of harmful plankton through ballast water |

| 3) |

The Japan Association of Marine Safety (1997): Study report on management

measures for ballast water onboard ship |

| 4) |

The Japan Association of Marine Safety (1998): Study report on management

measures for ballast water onboard ship |

| 5) |

The Japan Association of Marine Safety (1999): Study report on management

measures for ballast water onboard ships |

| 6) |

The Japan Association of Marine Safety (2001): Study report on reduction of

environmental impacts on marine ecosystem through ballast water associated with

ship's operation |

|