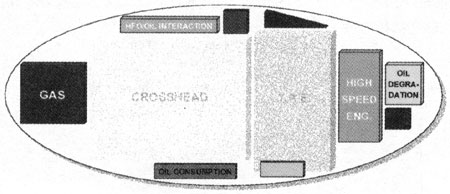

Fig. 4 - Cimac lube WG.

E. OIL CONSUMPTION OF MEDIUM SPEED DIESEL ENGINES.

The industry trend is toward the cost reduction. This means that all owners and engine builders are working to reduce lube oil consumption, and lube oil quantity inside the oil sump.

A typical flow chart through an engine is given in Fig.5, with lubrication parameters as follows:

Fig. 5 - Flow chart of oil.

Traditional Dry-Sump.

Generally the above is done by a dry-sump system which means that the oil is stored in a separate tank while engine crankcase is empty of oil charge. The above parameters suggest that the entire oil charge passes through the engine every 5 to 6 min. or 10 times per hour.

Dry-Sump, Reasonable Oil Consumption.

We can also say that, for a fairly large dry-sump oil charge (1.3 kg/kW) with the oil consumption of 1.0 g/kW.h the theoretical time of renewal of the oil charge is 1300-5800 hours (based on a 4000 kg oil charge for a 3077 kW engine as an example). See also Table 7. The stress suffered by the oil under such condition can as example be illustrated by a BN depletion curve as shown in Fig. 6a.

Fig. 6a - Typical evolution curve.

Broadly similar curves can be found (either on a decrease or increase trend) for other parameters such as pollution through insoluble level, metal etc.

Wet-Sump and Small Oil Charge.

The trend of some modern design engine is towards wet-sump, with or without low specific oil consumption. The wet-sump concept is to have the oil charge directly inside the engine, but for such case the oil quantity is smaller and can be as low as 0.2 to 0.4 kg/kW (instead of 1.3 kg/kW for dry-sump). This means that instead of passing 10 times per hour through the engine the oil charge is passing 30 to 40 times or every 1.5 to 2 minutes; in effect the oil will be subjected to more stress cycles and consequently be more rapidly stressed out. All phenomenon of attack will be speeded up. Being "fatigued" more quickly, the oil has to face demand of higher performance in terms of thermal resistance, ability to maintain its various characteristics such as anti-foam etc..., and higher reserve (such as BN for corrosion control and for detergency) will be needed etc. In situation of such very small oil charge (whilst on reasonable consumption/top-up rate), the oil characteristics/reserve "dive" to the final equilibrium very quickly although the level of the actual equilibrium level is unchanged and remained acceptable (see Fig. 6b). In severe cases - i.e. with additional severity of extreme low oil consumption - some oil characteristics and performance reserves may reach unacceptable limit before they could be helped by the oil top-up to reach an equilibrium - as explained below.

Fig. 6b - Typical evolution curve.

Low Oil Consumption.

In case of specific lube oil consumption, new design of ring package, liner and devices such as anti-polishing ring have enabled the oil consumption to reduce to 0.2 or 0.3 g/kW.h. This means that the refreshening of the oil-in-use by fresh oil top-up will be much slower/infrequent and sometimes becomes insufficient to keep the oil-in-use at satisfactory reserve/performance level.

BACK CONTENTS NEXT