|

Introduction of Toa Koki

Toyofumi Matsuo

Toa Koki Co., Ltd.

Toa Koki was established in June 1944, in the final phase of World War II, in Kashima City, Saga Prefecture in Western Japan. Until the end of the war in August 1 945, when electric power and materials were hard to come by in Japan, we were mainly engaged in the manufacture of parts for military items to the orders of Kawanami Shipyard located in Nagasaki City.

After the Second World War ended, we produced such castings for consumer use including pans and pots for household kitchens and stoves for space heating, which were then in short supply. Some time later, we began to produce engine parts for U.S. naval vessels, and by 1950 we were ordered to make cylinder liners for Mitsui Shipping Co. of Japan.

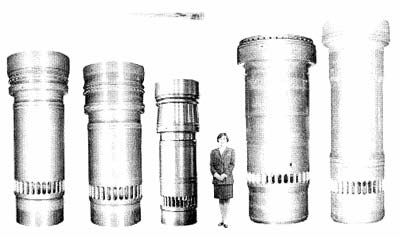

Cylinder liners, which are our main product item, are used in the heart of marine main diesel engines, and Japanese shipyards used to build cylinder liners in their own plants as they were aware of the vital importance of this item to diesel engines. However, the cylinder liners we began to manufacture on a regular basis in the late 1950s satisfied our customers, who appreciated the quality, the relatively low prices of our products and our punctual deliveries. This enabled us to establish ourselves as a specialized manufacturer of cylinder liners from the 1960s on, and we still enjoy this established position. We will see our 60th anniversary next year.

Early in the 1970s, we succeeded in practical application of Tarkalloy, a material then developed for use in racing car engines but considered incompatible with large marine main engines, to cylinder liners of such engines. When installed in a marine main engine built by a major Japanese shipyard, Tarkalloy-made cylinder liners proved more tenacious and resistant to wear than conventional products. This alloy is now used in cylinder liners for the large diesel engines of many vessels across the world.

The oil crises in the 1970s triggered a rising interest among Japanese shipyards in outsourcing the production of diesel engine parts from specialized manufacturers, and they did so. Today, we fully meet the demands for this item from the Kobe Shipyard and Engine Works of Mitsubishi Heavy Industries, Ltd., Hitachi Zosen Diesel & Engineering Co., Ltd., the Kobe Works of Kawasaki Heavy Industries, Ltd. and, more recently, Mitsui Engineering & Shipbuilding Co., Ltd. As our products installed in Japanese-built ships sail the seas all over the world, they have won the appreciation of service engineers abroad for their high quality. This resulted in our designation as a specialized manufacturer of cylinder liners by MAN B&W and Wartsila Switzerland, both well-known licensors of low-speed diesel engines, and our products are now used by engine builders in South Korea, China and Europe as well.

Our present manufacturing arrangement is such that raw castings are made at the Tanida Works, built in 1992, where the castings are roughly machined and the heat treatment. The intermediate products are then further machined and finally finished at the Yokota Works, which dates back to the founding of the company. The finished products, after going through inspection by LR or any other classification society concerned, are delivered to their respective users, who are our clients.

As your are well aware, diesel engines today are required to develop ever higher power outputs. To meet this requirement, parts which weigh as much as nine tons per unit at the maximum have to endure high temperature and abrasive force around the combustion chamber, which is the very heart of each engine. Under such circumstances, we acquired the ISO 9002 certificate in 1995, and are pursuing further enhancement of our technical capabilities to achieve even more strict quality management, develop even better materials and increase the precision of machining.

We are also making emphatic efforts in staff education to make it possible to hand over to future generations, and even further improve, the techniques and skills we have built up through our 60 year history. We are thus trying to make important contributions to steady operation of ships across the world. I hope this brief sketch of Toa Koki has interested you.

Noboru Asahara

Nakashima Propeller Co., Ltd.

First let me give you an overview of our company. Nakashima Propeller was founded in 1926, and will see its 77th anniversary this year. Ät present, we have a staff of about 350 persons. and the total sales of the Nakashima group amount to some Ä13 billion. Our headquarters and main factory are located in Okayama City, Japan. We have business offices in major cities in Japan, plus a well established post-delivery servicing network overseas.

The products we handle include the following:

- Fixed pitch propellers, ranging from 20 cm to 10 m in diameters, up to 100 tons in weight, including units of all sizes from small ones for pleasure boats, fishing boats and coastal ships to very big ones for 300,000 dwt VLCCs and 8,000 TEU class containerships;

- Controllable pitch propellers for all types of ships from oceangoing passenger ships to shuttle oil tankers;

- Side thrusters, both fixed pitch and controllable pitch types;

- Becker rudders

- Joystick control systems (NATACS)

- Water jets;

- Complete sets of shafting systems, and

- Steering gears.

Thus we can supply all kinds of propulsion system as total package supplier.

In particular in the Japanese market for large fixed pitch propellers for oceangoing ships, we hold an approximately 70% share, and in the world market for this item including South Korea, Taiwan and China, our share reaches about 30%.

Next, let me tell you what we aim at and what we do about propellers. First, we want to be a design-minded company, which is our corporate ideal or objective. Second, I would like to tell about keywords regarding propellers. The third of my topics is our investment in facilities and product development.

Regarding our ideal of becoming a design-minded company, we have developed as a specialized propeller manufacturer for almost 80 years. In the past, when hearing about a propeller, people tended to think first of a "casting" because of the way it was produced, and seldom to appreciate the propulsive performance a propeller carries out. So we thought we should give more emphasis on its design aspect, and decided to promote ourselves as a design-minded company. What we consider an ideal company is a company with an excellent design capability. What we mean by design capability is the ability to achieve the following.

1) Anticipating the needs of the times, and creating an innovative technology under the business policy of the company.

Concept and research

2) Flexibly applying technologies developed in other areas of specialization.

Applied technology

3) Incorporating basics and applications into the production systems of our main products.

Manufacturing

Linking these three key factors in a spiral form, we can go up every time we complete a turn. Our aim is to bring each such turn to bear on the quality of our products. Since realizing the target requires precise imaging of the product we want to create, design takes on an important role. The same may apply to the business image as well. You may often hear about R&D, which stands for research and development, but we add another D and think in terms of RD&D, that is, research, development and design.

Now, we come to the second theme, keywords regarding propellers. Regarding propellers, we have three technical keywords: efficiency, cavitation and strength. The relative weights of these three elements vary with the time. How we can successfully adapt ourselves to that variation determines the power of our corporate development. We have to anticipate the wave which would result from the variation in relative weight, and create a wave of our own. This is where the need for design-mindedness comes into the picture. Then, let me tell you which of the elements was given greater emphasis in one era or another in the environment of propellers, and how we have adapted to the shifting emphasis.

First, we saw an era of strength. In the earliest days of propellers, the overriding emphasis was on their freedom from breaking anyhow. To meet this requirement, we improved this aspect by changing the propeller material from cast iron to manganese bronze, and from manganese to nickel aluminum bronze.

Then came an era of efficiency. Since the 1970s, top priority was given to efficiency in pursuit of energy saving, and we met this requirement by creating low-speed large-diameter propellers.

Next came an era of living comfort. The interest in living comfort gave birth to pleasant propellers relatively free from vibration. This was embodied in high skew propellers.

The next keyword is cavitation. As ships became increasingly fast, interest was focused on super-cavitation propellers. For the speed range over 35 knots, surface propellers came into use.

Now, propellers meeting all these requirements are in demand. We have developed a new type PAL propeller, whose energy loss is reduced, and whose efficiency further enhanced, by having only the propeller blades eliminate the hub vortex.

Now I have come to my third theme, investment in facilities and product development by Nakashima. In plant facilities and equipment, we have actively invested since the 1970s. This has been focused on computer-aided designing and drafting. For this CAD process, we equipped ourselves with an NC blade surface machining device under five axis control for precise machining of complex three-dimensional blade surfaces. In 1981, we equipped ourselves for NC-machining the blade surfaces of propellers of all diameters from 20 cm to 10 m, and in 1995 acquired the ISO 9001 LR certificate.

Next, let me tell you the development of new type propellers. By applying the NASA's blade form theory and the finite element method of the University of Southern California in the U.S., we have developed a number of characteristic propellers. Among others, our high skew propeller made the subsequent world of propellers dramatically different from what it had been. An American manufacturer was ahead of us in developing a high skew propeller, but it was Japanese manufacturers that worked out high skew propellers which succeeded in penetrating the market as commercial products. High skew propellers involved some technical challenges that had to be met. They were sophisticated fluid analysis, sophisticated strength analysis and sophisticated three-dimensional blade surface machining techniques.

Looking at high skew propellers from the standpoint of a design-minded company, they called for:

Identifying the demand of the times (concept);

Developing elemental technologies as basics (research), and

Bringing peripheral technologies up to date (manufacturing).

Underlying all these aspects, there was the element of computerization.

While providing products developed on our own, we are also active in tying up with other major manufacturers, both at home and abroad. We have a technical license arrangement with Becker Marine Systems of Germany for flap rudders, and have already delivered some 3,000 units of this item for 2,500 ships. For small water jets, we have a sales cooperation agreement with Castoldi of Italy, and another with Schottel of Germany for specific propulsion systems including pump jet and rudder propellers. In Japan, we are working together with Ebara Corporation, one of the foremost pump manufacturers in the world, to develop a large water jet.

Thus, we at Nakashima consider it our mission to give the optimal shape to each individual requirements of our customers. To be able to do so, we constantly receive inputs of the most up-to-date technology and information by way of various routes, and wish to keep on improving our creative design capabilities all the time.

|